Fabrication is the process of creating a product from raw materials through a series of manufacturing processes. This involves cutting, bending, assembling, and joining different components to form a finished product. While the term can be applied to various materials, it’s most commonly associated with metalworking.

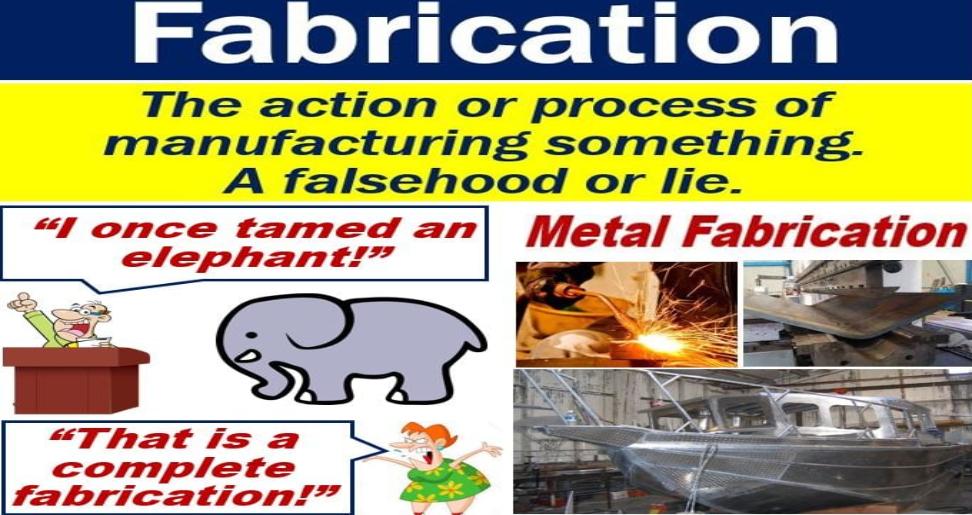

“A fabrication” may mean a lie

A fabrication is essentially a constructed falsehood.

It implies the deliberate creation of a story or account that bears no resemblance to reality. While the term can also refer to the physical creation of something, in the context of language, a fabrication is a lie, a purposeful distortion of truth intended to deceive or mislead.

Metal fabrication

Metal fabrication is the intricate process of transforming raw metal materials into desired shapes and structures. It involves a series of techniques, including cutting, bending, and assembling, which are executed with precision and skill. From the initial design phase to the final assembly, fabricators employ a combination of manual craftsmanship and advanced technology to create a vast array of products. This versatile field encompasses everything from small-scale components for machinery to large-scale architectural structures, demonstrating the boundless possibilities of metalworking.

Etymology of fabrication

The word “fabrication” traces its origins back to the Latin term “fabricare,” meaning “to make, construct, or fashion.”Initially, fabrication referred to the process of creating something tangible, such as a building or a piece of machinery. The noun form, “fabricatio,” evolved to describe the act of constructing or manufacturing. Over time, the word’s meaning expanded to encompass the creation of intangible things, including stories, evidence, or excuses. This shift occurred in the 18th century, giving rise to the negative connotation of fabrication as the deliberate creation of falsehoods or deception. Thus, while the word’s root implies a constructive process, its contemporary usage often carries a pejorative sense.

Key phrases in the world of “Fabrication”

Fabrication, at its core, revolves around transforming raw materials into finished products. Central to this process are terms like ‘machining,’ ‘welding,’ and ‘forming,’ which encompass techniques to shape and join materials.

- Fabrication Techniques

Fabrication encompasses a diverse array of processes that transform raw materials into finished products. These techniques involve cutting, shaping, and joining materials to create components or assemblies. Common methods include cutting (shearing, laser cutting, waterjet cutting), forming (bending, stamping, rolling), and joining (welding, riveting, adhesive bonding). The specific techniques employed depend on factors such as material type, desired product shape, production volume, and cost considerations. Advanced technologies like computer numerical control (CNC) machinery and automation have significantly enhanced fabrication precision and efficiency, enabling the production of complex and intricate components across various industries.

- Fabrication Plant

A fabrication plant is an industrial facility where raw materials are transformed into finished products through a series of manufacturing processes. This complex operation involves cutting, bending, welding, and assembling components to create structures or equipment. Equipped with heavy machinery and skilled labor, these plants are typically large-scale operations that require advanced technology and strict quality control measures. Fabrication plants serve a wide range of industries, from construction and automotive to aerospace and energy, producing everything from steel beams to intricate metal components.

- Fabrication Process

Fabrication is a manufacturing process that transforms raw materials into finished or semi-finished products. This involves a series of techniques to shape, cut, or mold materials into desired forms. Common fabrication methods include cutting, bending, forming, and joining processes like welding or riveting. The process begins with selecting suitable raw materials based on the product’s requirements. These materials are then cut into specific shapes and sizes using tools such as saws, lasers, or water jets. Subsequently, the cut pieces undergo forming processes like bending, stamping, or rolling to achieve the desired contours. Finally, the shaped components are joined together using techniques like welding, bolting, or riveting to create the final product. Fabrication can be carried out manually, mechanically, or through automated systems, offering versatility and precision in manufacturing various components and structures.

- Fabrication Cost

Fabrication Cost encompasses the total expenditure incurred in transforming raw materials or components into a finished product. It comprises a multifaceted array of expenses, including the cost of raw materials, labor involved in fabrication processes, energy consumption, machinery depreciation, overhead costs associated with the production facility, and quality control measures. Additionally, external factors such as market fluctuations in material prices and fluctuations in labor costs can significantly impact the overall fabrication cost. Effective cost management strategies are crucial for optimizing profitability and maintaining competitive advantage in manufacturing industries.

- Fabrication Workshop

A fabrication workshop is a specialized environment equipped with machinery and tools designed to transform raw materials into finished products through processes like cutting, bending, welding, and assembly. These workshops are typically found in manufacturing industries, but they can also serve as educational or research spaces. Within their confines, skilled technicians and engineers manipulate metals, plastics, or other materials to create a vast array of components and structures, ranging from simple brackets to complex machinery and architectural elements. The precision, expertise, and heavy-duty equipment employed in fabrication workshops are essential for producing items that meet stringent quality and safety standards.

The Fabrication Process

The fabrication process typically involves several steps:

- Design and Planning: Design and Planning is a meticulous process that involves conceptualizing, organizing, and strategizing to achieve a specific goal. It encompasses a systematic approach to problem-solving, where ideas are transformed into tangible solutions. This phase is critical as it lays the foundation for successful execution, ensuring that resources, time, and efforts are allocated efficiently. Through careful analysis, designers and planners identify objectives, define constraints, explore alternatives, and ultimately create a blueprint for action. This comprehensive framework guides decision-making, minimizes risks, and optimizes outcomes, making it an indispensable component of any undertaking.

- Material Selection: Material selection is a critical phase in product development, influencing performance, cost, and sustainability. It involves meticulously evaluating a range of materials based on their properties, considering factors like strength, durability, weight, corrosion resistance, and processability. The ideal material optimizes product function while meeting constraints such as cost, availability, and environmental impact. Engineers often employ material indices and performance indices to streamline selection. Furthermore, modern design emphasizes sustainable choices, prioritizing materials with minimal ecological footprint, recyclability, and efficient lifecycle management. Ultimately, informed material selection is pivotal in creating products that are not only functional but also responsible and cost-effective.

- Cutting: Cutting is a precise and often delicate action that involves the separation of a material into two or more parts using a sharp implement. This process can be as simple as slicing through a piece of paper with scissors or as complex as surgically removing tissue with a scalpel. The nature of the cutting tool and the material being cut dictates the technique employed, from the gentle pressure applied to a soft substance to the forceful impact required for harder materials. Whether it’s a carpenter shaping wood, a chef preparing ingredients, or a tailor altering fabric, the act of cutting is fundamental to countless human endeavors.

- Forming: Formation is a process of creation, a methodical assembly of disparate elements into a cohesive whole. It can be a gradual evolution, like the shaping of a planet over millennia, or a rapid construction, such as the erection of a skyscraper. Whether physical or conceptual, formation implies a progression from chaos to order, a transformation guided by intrinsic or external forces. This dynamic process is evident in the growth of an organism, the development of a theory, or the establishment of a society. At its core, formation is a fundamental aspect of existence, a constant interplay between stasis and change.

- Welding or Joining: Welding is a fabrication process that permanently joins materials, primarily metals or thermoplastics, by melting and fusing them together. This is typically achieved through intense heat application, often accompanied by pressure or a filler material. While welding is the most common method, joining encompasses a broader spectrum of techniques. These include lower temperature processes like brazing and soldering, which utilize a filler metal that melts below the base material’s melting point, as well as solid-state welding methods that bond materials without melting them. The choice of joining method depends on factors such as material type, desired joint strength, and application requirements

- Finishing: Finishing is the culmination of a process, a final touch that transforms raw potential into a polished masterpiece. It demands meticulous attention, a keen eye for detail, and an unwavering commitment to excellence. Whether it’s the last stroke on a canvas, the concluding chord of a symphony, or the final edit on a written piece, finishing requires patience, perseverance, and a deep-seated satisfaction in bringing something to completion. It is in those final moments that the true essence of a creation is revealed, leaving a lasting impression on those who encounter it.

- Assembly: An assembly is a formal gathering of people, typically for a specific purpose or occasion. It can range from a small, localized group to a large, representative body. In a political context, an assembly is often a legislative body, such as a parliament or congress, where elected representatives convene to make laws, debate policies, and govern. However, the term can also refer to other types of gatherings, including religious congregations, educational assemblies for students, or corporate meetings. The common thread is a structured format where individuals come together to share information, make decisions, or participate in a collective activity.

Read More :

Featured Image Source: https://tinyurl.com/mr4xax5w